Digital printing

What does digital printing mean?

Digital printing is a digital printing process that does not require any printing forms, such as stamps or stencils. This printing method works purely digitally. There are some additional terms for digital printing including direct digital printing (DDP) and computer-to print.

How does digital printing work?

Digital printing really sets itself apart from all other printing technologies, like offset printing. It does that by transferring the respective print image from a file via a computer directly to a printer or printing press. Through this action, the digital print is implemented with impressive speed during printing. What makes this printing process really special is that, unlike offset printing, there is no need for a solid or static print body during printing. This means that when printing, no print body is needed in advance for the colors that should be printed, but they are applied before the actual printing takes place.

Inkjet process in printing

In inkjet printing, the digital image is recreated on physical surfaces by propelling droplets of ink onto the surfaces. This type of printing process allows printing on very large areas, areas which are only limited by the paper size itself. Even though the printing speed of inkjet technology is limited, it cannot be matched in terms of printing as it has a very high quality and resolution.

Laser printing process

Laser printing is a more complex digital printing process than inkjet printing. For this reason, laser printing requires various processes before the ink is finally applied to the paper or material. Inside the printer there is a roller, also called an image drum, which has a negative electrical charge. After that, this roller is bombarded with a laser in order for it to lose the negative charge in some places. A powder called toner, which acts as a printing ink, is applied to the roller and, because it also has a negative charge, the toner only adheres to the areas that have been bombarded with the laser. The printing paper is passed between the image drum and a drum with a positive charge, so that the toner reaches the paper or printing material and is fixed with the help of pressure and heat. However, only one color pigment reaches the paper in such a process, which is why laser printing requires four image drums to serve each color in the printing process. The laser printing process is often used for printing long runs.

Both printing technologies offer the possibility of creating an unlimited number of different printed images in the process, as they do not rely on pre-made templates for printing. These techniques are also good for bulk orders as with their speed and efficiency, it is possible to print on a much larger scale.

When is digital printing used?

Of all the printing methods, digital printing is probably the most well known. This type of printing method is not only used in the production of advertising materials, but it is also used by most people on a daily basis. Nowadays, you can find an inkjet or laser printer in just about every office or household because it can be used to print out documents, pictures or letters very easily and quickly. For mass production of promotional items though, there are completely different printing calibers available compared to the mode of operation from the small digital printers at the office. Large format digital printing is typically used for printing on flat surfaces, like banners, adhesive films, signs, flags and many other objects.

Difference between laser printing process and inkjet printing process

The two printing techniques of digital printing have noticeable differences so depending on the print motif, it is important to pay attention to these specific differences.

- Black and white and color printing

A pure black and white text print is produced with the laser printing process significantly more qualitative and high-quality. When printing letters, they have sharp, smooth edges and impressive color brilliance. They are very resistant to contact with moisture and sunlight, which makes laser printing particularly suitable for promotional items that will be in use for a long time and or are being used outside in the elements. The type of paper used for printing does not play a significant role, as the advantages of this printing technique are always present. However, if you decide to finish promotional gifts with color images or photos, you should opt for the inkjet printer when printing. Even though the printing process is somewhat slower than the laser, this method ensures extremely accurate transfer of the original and intended colors to the paper. With laser printing, on the other hand, fluctuations in temperature and humidity during printing can lead to differences in the quality of the printed photos.

- Print resolution

In the next phase, print resolution, inkjet printing again emerges as the winner. This is measured in DPI, dots per inch, which refers to the number of ink dots that the printer can distribute over one inch. Where laser printers achieve a maximum DPI count of 1200, inkjet printers manage eight times that amount. This allows photos and color images to be printed in crisp resolution. For products that need a clean and precise typeface, the laser printer is always suitable and preferred.

Color options in digital printing

To ensure that type, like an advertising message, can be perfectly implemented and corresponds exactly to the original ideas, special care should be taken when creating the print file. By doing so, this ensures that the required color space is adhered to. Most print shops use the CMYK color space as standard, but it is safer to ask the specific print shop about the color space in advance to avoid any miscommunication. If there are any deviations, the final color shades may differ from the original as they might be weaker than expected.

What are the digital printing costs?

The cost of printing with digital printing is based solely on the number of runs it will take to print all your items. As already mentioned, since this technique does not require the creation of artwork or the use of special tools for different colors, it is only necessary to know how many promotional products need to be printed.

Digital printing advantages

- Unlimited printing possibilities: The complete digitization of this printing process removes virtually all restrictions on the color and shape of a printed motif. Meaning you are only limited by your imagination.

- Quality: Photo and color prints are produced to a high standard using inkjet technology in digital printing. The result is impressive color intensity and a high-quality resolution.

- Speed: Digital printing has an extremely fast production speed when printing. You no longer need to wait very long for the object to be printed.

- Cost-effectiveness: Even for small orders, this technology is extremely cost-effective for printing. The fact that digital printing does not require the production of a manufactured print template or the use of special tools for printing inks makes digital printing an extremely cost-effective printing process. Therefore, this type of printing is ideally suited for companies with a small marketing budget.

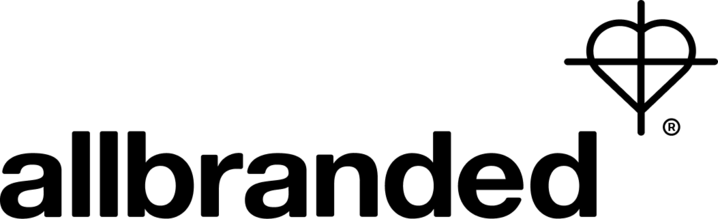

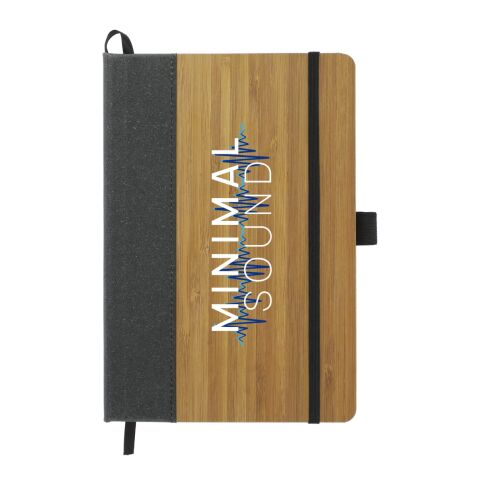

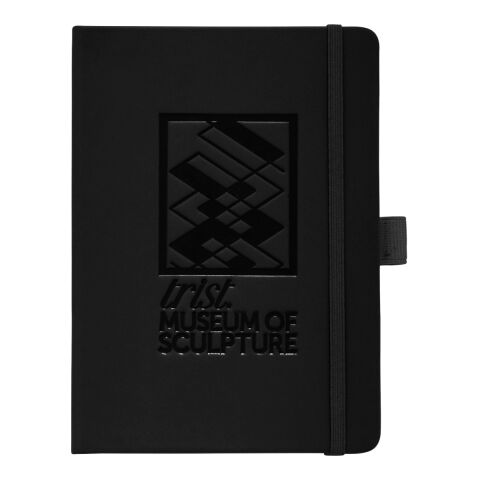

Which promotional items are suitable for digital printing?

Promotional items made from paper or cardboard are most suitable for digital printing. These types of products are especially good for digital printing because they have a smooth and even surface. However, basically any product that has a flat, smooth surface would work best with digital printing. Digital printing is particularly advantageous as giveaway items because of its extremely low production costs. Whether practical sticky notes or promotional pens with company logos are to be distributed at the next trade show or notebooks are to be given away during back to school, digital printing produces excellent print results. Recipients are most pleased with long-lasting and useful promotional items compared to items they may not use very often. Printing business merch with a logo not only brings a company into contact with potential customers, but also increases their appreciation of and trust in the company. It is also very well received to present a promotional gift in a nice package branded with a logo to increase the anticipation when unwrapping it. Since digital printing is not bound to a fixed artwork or design when printing, each side of the packaging can be printed individually. This is what makes digital printing so popular among all the printing processes available. Printing versatility like this is important in the promotional product industry.