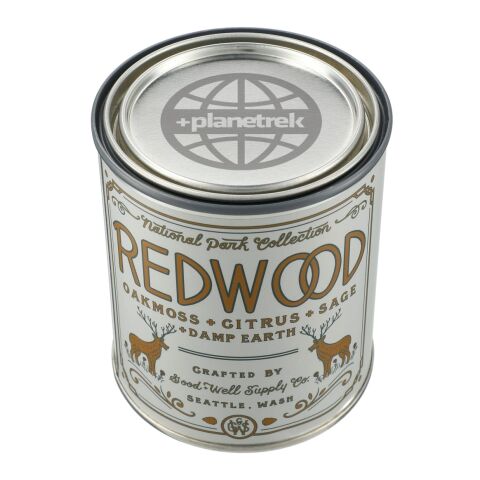

Laser engraving

The term laser engraving refers to a type of finishing where motifs or logos are burned into an object with a laser beam. A laser can be used to reliably engrave complex information in a very precise manner. Even the smallest objects are no challenge for this type of finishing, which makes laser engraving a practical engraving method. Engrave things from pens to water bottles without losing quality.

How does laser engraving work?

Laser engraving is essentially a wide variety of materials that are enhanced with an inscription, logo or graphic using a laser beam. Laser engraving is the most modern standard in the field of engraving and is often used for advertising materials because of its high quality production. In contrast to laser printing with a weak laser beam, laser engraving not only changes the pigment application, but also the material itself. The extreme heat of the laser vaporizes or burns the material into the specified pattern or design. In this way, the printing becomes visible and it is separated from the surface. The laser either passes over the surface line by line or draws individual contours, but does not come into contact with the promotional product. The coloring is created on organic materials such as paper, wood or cardboard by the laser generating chemical conversion reactions by locally heating the material. Another laser technology variant is color removal. In this case, the coating is removed from coated materials without contact with the promotional item, revealing the underlying color.

Endless possibilities for engraving information with the laser

Laser engraving is possible on almost any solid surface such as glass, wood, porcelain or metal. These include ballpoint pens, thermos bottles, USB sticks, pocket knives or high-quality flashlights. However, Christmas presents are also particularly suitable for laser engraving as it brings a bit more high-end quality to the product. Laser engraving offers endless possibilities for individualization, such as engraving texts, logos, graphics, pictures, numbers, drawings and even complex designs like fingerprints. Even designs like handwriting can be engraved using computer-controlled laser technology.

What are the advantages of laser engraving?

Laser engraving is characterized by numerous advantages that make this type of finishing so popular in its use.

- Advertising effectiveness:

One of the biggest benefits is the eye-catching advertising effect created by the sophisticated engraving of the promotional item. This finishing option can directly appeal to the emotions of the target audience. Through this appeal and emotions, the product can create lasting advertising that is sure to be remembered. An elaborate laser inscription not only creates wow effects for the person receiving the gift, but also shifts the advertising effect to a more professional environment.

- Free choice of design:

Laser engraving allows a completely free design of the engraving template. From logo to slogan to graphics, drawings and handwriting, almost anything is possible.

- Accuracy:

Another advantage is the distinction of attention to detail. Accordingly, even particularly fine lines are projected clearly and cleanly onto the object in question. You don’t need to worry about complex designs, as it is possible to achieve your desired effect using laser engraving.

- Durability:

In addition, this printing technology impresses with the highest abrasion resistance and water resistance. That means, whatever you choose to engrave on your product, individual motifs such as logo, slogan or a text message, last on the promotional gift for a long time and are more difficult to remove. An engraved promotional gift therefore not only reaches the primary target group, but also people in their immediate environment. This durability of laser engraving means your recipient will remember your brand long after the initial event.

- Gentle production:

Engraving with a laser is a non-contact process, which means the laser does not come into contact with the article during the engraving process. As with conventional engraving, there is no need to fix the product in place. Due to the absence of mechanical stress, the item completely retains its robustness.

- Speed:

Complementary to conventional engraving techniques, laser engravings are created in almost no time at all. Compared to other printing methods, such as transfer printing or pad printing, laser engraving is also distinguished by a fully automatic and fast process. Therefore, even short-term advertising campaigns can be implemented with a creative advertising text, logo, company name or web address.

- Cost-effectiveness:

Engraved items can also be produced in smaller runs, and in a fairly cost-effective price range. The cost makes it possible to bulk order more items with an engraved logo without going over your budget.

- Environmental friendly:

Companies that focus on sustainability in their corporate philosophy benefit additionally, as laser engraving has no negative impact on the environment. This is mostly due to the absence of harmful substances and solvents.

Which promotional items are best suitable for laser engraving?

There are many different applications and possible uses for laser engraving. Wherever it may be that special attention is needed, engraved promotional items are the ideal brand ambassador for companies. Whether as a thank you for a successful cooperation and partnership with business contacts, to celebrate a successful year, as a Christmas present for clients and employees or as a gift for the most profitable and loyal existing customers. There are many possibilities to present a company in the best possible way with a laser engraving. The prerequisite for this is that the promotional item has a smooth surface, as is the case with glass, wood, leather or porcelain, for example.

Useful flashlights, travel mugs, tools or even cutlery look much more valuable with a high-quality laser inscription. A stamp also makes a greater impression with a wooden engraving and creates a small feeling of elation among employees every time there is something to stamp. Even food containers and storage can be engraved, as it will not be harmless to your health. If you don't have the budget for expensive promotional gifts, that doesn’t mean that you have to do without laser engraving. The filigree laser technology also allows the decoration of smaller and less expensive promotional gifts, such as USB sticks, key chains, ballpoint pens, coffee mugs or power banks.

What color options are available for laser engraving?

For a little more color in laser engraving, there are two variations that can be used to engrave promotional items.

- Temper marking:

In this process, the laser hits metal, which heats up in the process, again causing a color change. The reaction of heat and oxygen causes the metal color to change, making the engraving stand out even more clearly from the item material than before the laser engraving. It is important to note that the material is only heated, not vaporized. This process is only suitable for things made of metal, like tools, metal water bottles, or magnets.

- Color envelope marking:

This technique alters the molecules of the item material due to the enormous amount of heat applied to it by the laser, which in turn gives the color a different appearance. The engraved motif stands out visually from the background, while the surface of the advertising medium remains virtually undamaged.

What both variants have in common is that at the end of engraving, precise and high-contrast lines are created, some of which can be felt on the surface of the workpiece.

Laser engraving costs

As the investment costs for laser marking systems are low and the running costs for the machines are also low, the engraving of advertising materials and company swag is also becoming increasingly affordable. Some of the fixed costs include program creation and setup of the marking system. In addition to these fixed costs, there are the unit costs for the laser process. You do not need to worry about high production costs. Even for smaller quantities, laser engraving can be completed within a reasonable economic framework and within a short time, because engraving with a laser is one of the fastest types of finishing.